Comparison of Methods

Active discharging systems

The active discharging systems that are currently available on the market differentiate themselves essentially in the type of applied voltage to the high-voltage needles. These types range from common AC voltage through pulsed DC voltage all the way to the Kersten patented continuous bipolar DC volt technology. The Kersten patented DC volt technology continuously generates the maximum amount of ions possible. As a result, temporal and spatial discharging gaps become a thing of the past. The continuous DC volt technology can be applied anywhere that strong discharge power is needed

Using continuous DC

Using continuous DC volt technology provides other benefits besides strong discharging power. Other benefits include the compact construction of the discharging components, as well as good EMC (electromagnetic compatibility) values. Therefore, the discharging components are able to be positioned into areas, where because of a lack of space it would not normally be possible to achieve an optimal discharge. Continuous DC volt technology can be applied across all areas of industry. Kersten also offers special Ex-Range discharging systems with the continuous DC volt technology. This is for areas where an explosion-hazardous atmosphere makes regular discharging impossible. The Kersten DC discharging systems are a Plug-In system. All discharging components can be connected to the specifically designed high voltage power supply. The specially developed reverse polarity protected high-voltage plugs are unique on the market. They provide an operating safety like no other competitor offers. In order to expand the number of high-voltage plug-in slots, optional high-voltage distributers can be used. This makes subsequent expansions or additions much easier.

Comparison of Methods / Illustrating the Benefits of the Patented KERSTEN Procedure

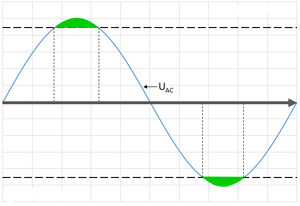

Discharging AC

- Discharge gaps in which no discharging takes place at all.

- Only ions of one polarity are provided between the gaps. i.e. discharge only at the time when the material is oppositely charged.

Discharging AC / DC pulsed

- Only ions of one polarity are provided between the gaps.

- No impact ionisation between the electrode needles.

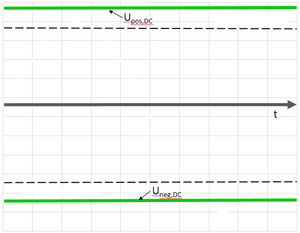

Patented DC Discharging by Kersten Elektrostatik

- Constant supply of an ion reservoir of both polarities

- Maximum discharge power, regardless of the charge of the material

- Highest ion output amongst competitors

The patented discharging method optimally supports your processes compared to other commercially available methods. The process ensures a simultaneous and continuous ion supply of both polarities. This is independent of material properties or process speed.

Thus, you are able to achieve the best possible results without the use of expensive measuring and control technology. This is because the required positive and negative ions are made available for discharging at all times without subsequent intervention on the material.